- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

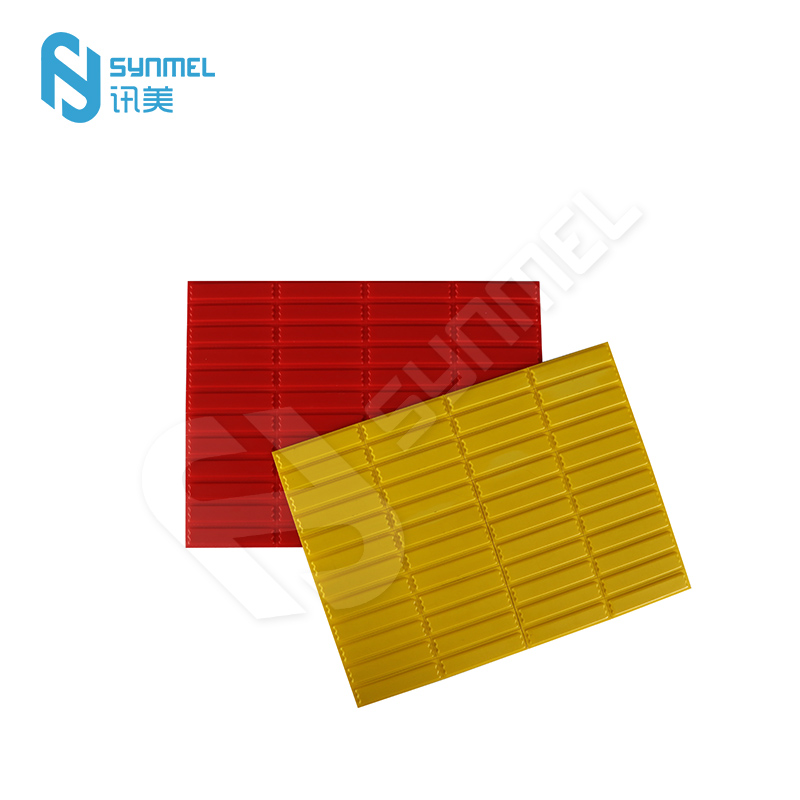

Are AM color labels corrosion resistant?

2025-10-31

The corrosion resistance of AM color labels depends on the materials used and the outer coating. Typically, AM labels consist of a plastic shell and an electromagnetic induction chip. The shell material is usually polyester or polypropylene, which offer some corrosion resistance.

Key factors for label corrosion resistance:

Shell Material:

Polyester: PET material itself has good chemical and corrosion resistance, resisting certain acids, alkalis, and moisture. It is commonly used in electronic devices and label shells.

Polypropylene: PP also has good corrosion resistance, especially when in contact with weak acids or alkalis.

Coating Protection:

UV Coating: Some AM labels have a UV-resistant coating, which not only protects the label from UV damage but also enhances its corrosion resistance.

Waterproof Coating: Some labels have an additional waterproof layer, better preventing moisture damage, especially in humid environments, extending their lifespan.

Chip Encapsulation: The electromagnetic chip inside the label is usually well-encapsulated to prevent corrosive liquids from entering the chip area, ensuring long-term stable operation.

Environmental Impacts:

Moisture and Chemicals: While most AM labels possess some degree of corrosion resistance, this resistance can be compromised in extreme environments.

High Temperature: Prolonged exposure to high temperatures can also cause label materials to age, affecting their performance.

Summary: AM color labels typically exhibit some corrosion resistance in everyday environments, especially in retail settings, and can withstand common environmental factors such as moisture and dust. However, long-term exposure to extreme chemical or temperature/humidity conditions may shorten their lifespan.